1. Mining and Smelting Aluminum: From Ore to Metal

The production of aluminum begins with mining its primary ore, bauxite. Bauxite, abundant worldwide, undergoes a complex chemical extraction process to produce alumina, which is then smelted to produce aluminum metal through electrolytic reduction. This process is highly energy-intensive and generates some carbon emissions, making aluminum production demanding in terms of environmental and energy resources.

Among the world’s leading aluminum producers, Rio Tinto and Alcoa stand out. Rio Tinto, headquartered in the UK and Australia, is one of the largest mining companies globally and a pioneer in the production of low-carbon aluminum. Alcoa, based in the U.S., has been a leader in aluminum innovation and sustainability efforts, often using renewable energy sources in its production processes. Both companies play significant roles in ensuring the global supply of high-quality aluminum, which benefits industries like aluminum case manufacturing.

Increasingly, aluminum producers are focusing on green aluminum production by using renewable energy to reduce carbon emissions. Aluminum is also highly recyclable, with recycled aluminum using only about 5% of the energy required for primary production. This trend toward recycled aluminum is gaining traction in the industry, signaling a positive development for environmentally conscious consumers.

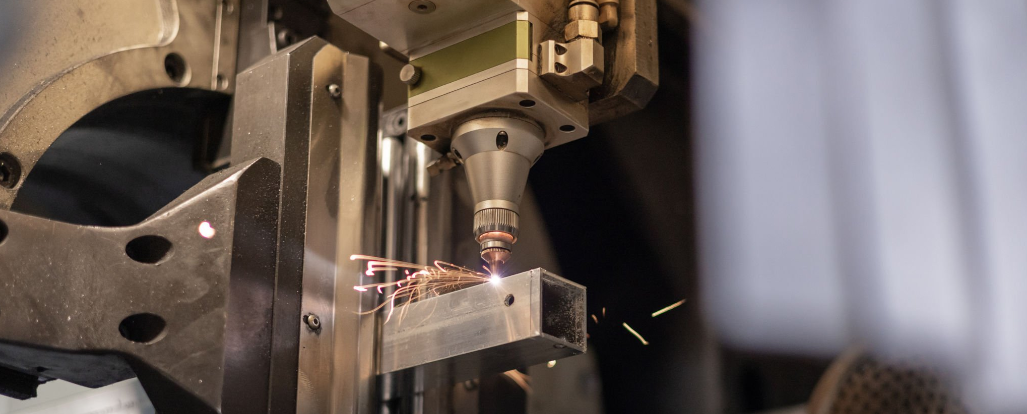

2. Aluminum Case Processing: Shaping Aluminum’s Unique Form and Properties

Once aluminum ingots are produced, they’re sent to processing facilities to undergo rolling, extrusion, and other treatment processes, shaping them into sheets, coils, or profiles of various sizes and specifications. Different uses of aluminum cases require different types of aluminum materials: lightweight cases may prioritize weight control, while protective cases may use thicker aluminum for added durability.

Some of the world’s top aluminum processors include Hydro, Chalco, and Novelis. Hydro, a Norwegian company, is well-regarded for its commitment to sustainable aluminum solutions and focuses on producing high-quality aluminum for diverse applications. Chalco (China Aluminum Corporation) is a major Chinese producer known for its expansive aluminum operations, including mining, processing, and recycling. Novelis, a U.S.-based leader in rolled aluminum products, focuses extensively on recycling, contributing to the sustainable production of high-quality aluminum materials for industries like automotive, packaging, and specialty applications, such as aluminum cases.

Surface treatment is also crucial in this stage. Anodizing aluminum not only improves corrosion resistance but also enhances its appearance, offering more color and luster options. These processing details have a direct impact on the final quality and lifespan of aluminum cases.

3. How Aluminum Quality and Cost Affect Aluminum Case Pricing

As consumers, understanding the production and processing of aluminum helps us better appreciate the cost structure of aluminum cases, and it also enables us to make more informed choices when buying. For example, choosing brands that use certified recycled aluminum or high-quality materials ensures not only a superior product but also supports environmentally responsible production.

In the cost structure of aluminum cases, aluminum materials represent a large proportion. Fluctuations in aluminum prices directly affect the market price of aluminum cases. For instance, global aluminum prices can rise sharply due to supply-demand changes or energy price shifts, which is especially impactful for case manufacturers relying on high-quality aluminum. This price volatility ultimately influences consumers.

4. Future Trends: Greener, Lighter

As consumers, understanding the production and processing of aluminum helps us better appreciate the cost structure of aluminum cases, and it also enables us to make more informed choices when buying. For example, choosing brands that use certified recycled aluminum or high-quality materials ensures not only a superior product but also supports environmentally responsible production.

In the cost structure of aluminum cases, aluminum materials represent a large proportion. Fluctuations in aluminum prices directly affect the market price of aluminum cases. For instance, global aluminum prices can rise sharply due to supply-demand changes or energy price shifts, which is especially impactful for case manufacturers relying on high-quality aluminum. This price volatility ultimately influences consumers.

Post time: Nov-08-2024