Today, let's talk about a metal that is ubiquitous in our lives—aluminum. Aluminum (Aluminium), with the element symbol Al, is a silvery-white light metal that not only exhibits good ductility, electrical conductivity, and thermal conductivity but also possesses a series of unique physical and chemical properties, making it widely used in numerous fields.

Aluminum is the most abundant metallic element in the Earth's crust, after oxygen and silicon. Its density is relatively low, and its texture is soft but harder than magnesium, with a good strength-to-weight ratio. These properties make aluminum an important material in aerospace, automobile manufacturing, the construction industry, electronics, packaging materials, and many other industrial fields.

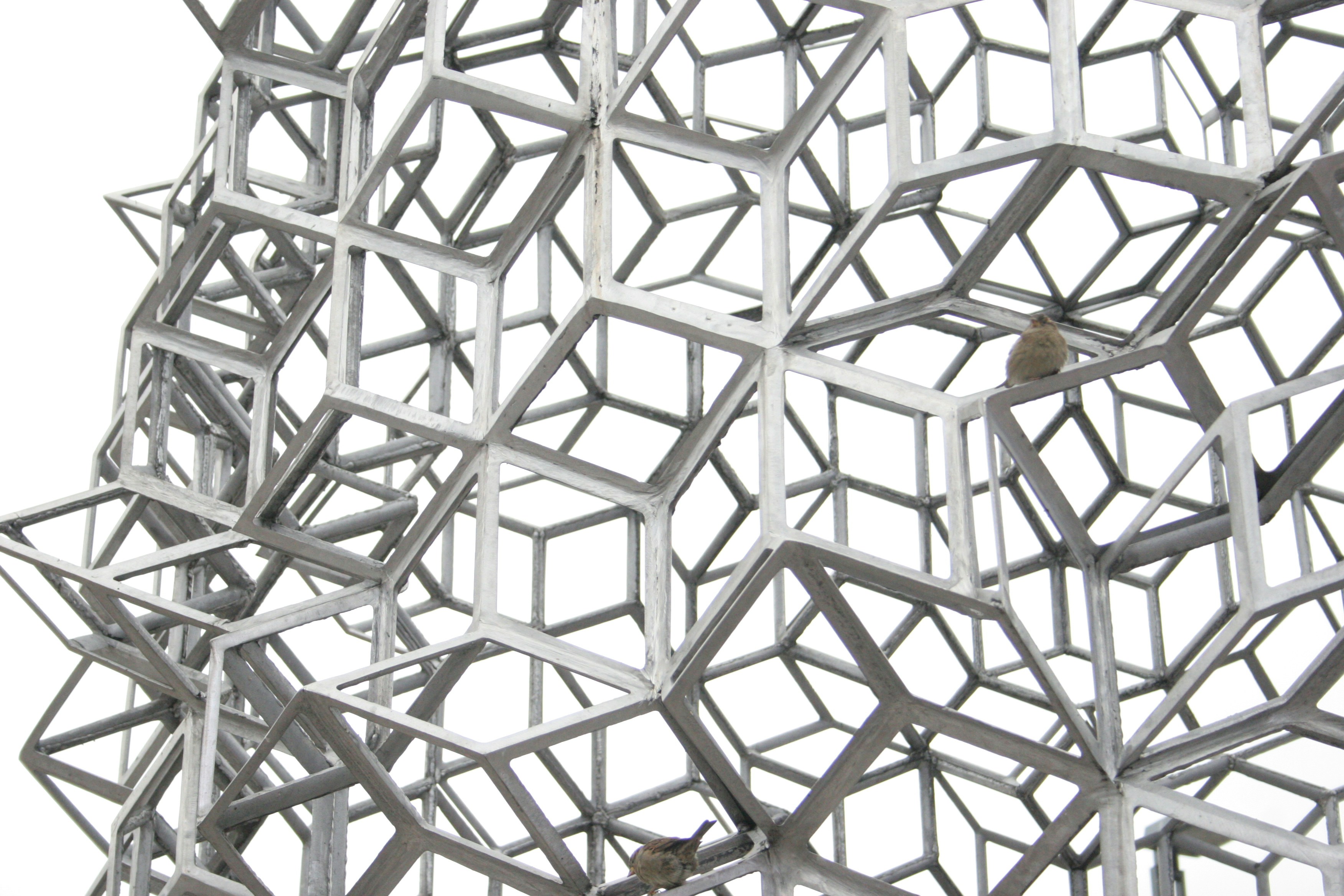

In the construction industry, aluminum materials are widely used in doors, windows, curtain walls, and structural support systems due to their good weather resistance and ease of processing. With the acceleration of global urbanization, the demand for aluminum in the construction industry remains stable and growing. The surface of aluminum has a dense oxide protective film that prevents metal corrosion, so it is also widely used in the manufacture of chemical reactors, medical devices, refrigeration equipment, oil refining equipment, etc.

Aluminum also has extensive applications in the electronics and packaging industries. In electronics, aluminum is used for heat sinks and casings, which can effectively dissipate heat and protect internal components from overheating damage. In the packaging field, aluminum foil, due to its good barrier properties, can effectively isolate light, oxygen, and moisture—the three main factors that often lead to food spoilage. By isolating these factors, aluminum packaging materials can extend the shelf life of food and maintain its nutritional content and taste, thus ensuring product quality and safety in food and pharmaceutical packaging.

Because of its lightweight strength, corrosion resistance, and ease of processing, aluminum is also widely used in the aluminum case industry, becoming an ideal material for manufacturing diversified and high-performance aluminum cases. It meets the needs of various industries such as beauty and salons, tool combinations, instrumentation, and electronic communications, and is the preferred casing for high-end instrumentation. In the food, pharmaceutical, and other fields, aluminum cases are also commonly used for storing, transporting, and selling related products due to their good moisture resistance, protective properties, and thermal insulation performance.

The wide application of aluminum cases in multiple fields is inseparable from their ease of processing. Aluminum and its alloys generally have good plasticity and can be easily processed into various shapes and sizes through plastic processing methods such as rolling, extruding, stretching, and forging. These processing methods not only ensure the dimensional accuracy and mechanical properties of the products but also provide good surface quality to meet various complex application requirements.

In general, as a lightweight and powerful metal, aluminum has demonstrated a wide range of application prospects in multiple fields. Its unique properties not only meet various complex application requirements but also promote the development and innovation of related industries. I hope through this blog, you can have a deeper understanding of aluminum and recognize the importance of this metal in our lives.

Top of page

Post time: Nov-22-2024